Sustainability-based technologies

Centrifugal forces separate dust from the airflow, making a dust bag unnecessary. We use a powerful airflow instead of energy-intensive heating technologies to dry hands. Sustainability has always been a central focus for us at Dyson.

Reshape

We support educational programs to foster and inspire the next generation of engineers to develop solutions to today's problems. Through various awards and prizes, we also aim to encourage them in a special way and recognize their achievements.

Investments in a better future

Investments in a better future

Innovative technologies to solve tomorrow's problems

This is a crucial issue not only for Dyson, but for the entire world. Great technological ambitions require the best engineers. However, a lack of young talent can hinder progress. That's why we founded the Dyson Institute. In this way, we aim to transform and revolutionize education.

We inspire young inventors to drive change.

The James Dyson Foundation is Dyson's own charitable foundation for education. It aims to motivate aspiring inventors to develop solutions to problems.

We are advancing medical and scientific research.

The James Dyson Foundation, in partnership with Race Against Dementia, is funding a research fellowship for Alzheimer's and dementia studies. Dr. Claire Durrant is utilizing Dyson's expertise and our research laboratory in Malmesbury to analyze brain samples at a microscopic level.

Imagine

Our development team works closely with Dyson Farming. The use of new technologies, combined with a large dose of ingenuity, enables us to grow food on a large scale and responsibly, while also taking land and nature conservation initiatives into account.

Responsible and large-scale food production using technology and ingenuity

Responsible and large-scale food production using technology and ingenuity

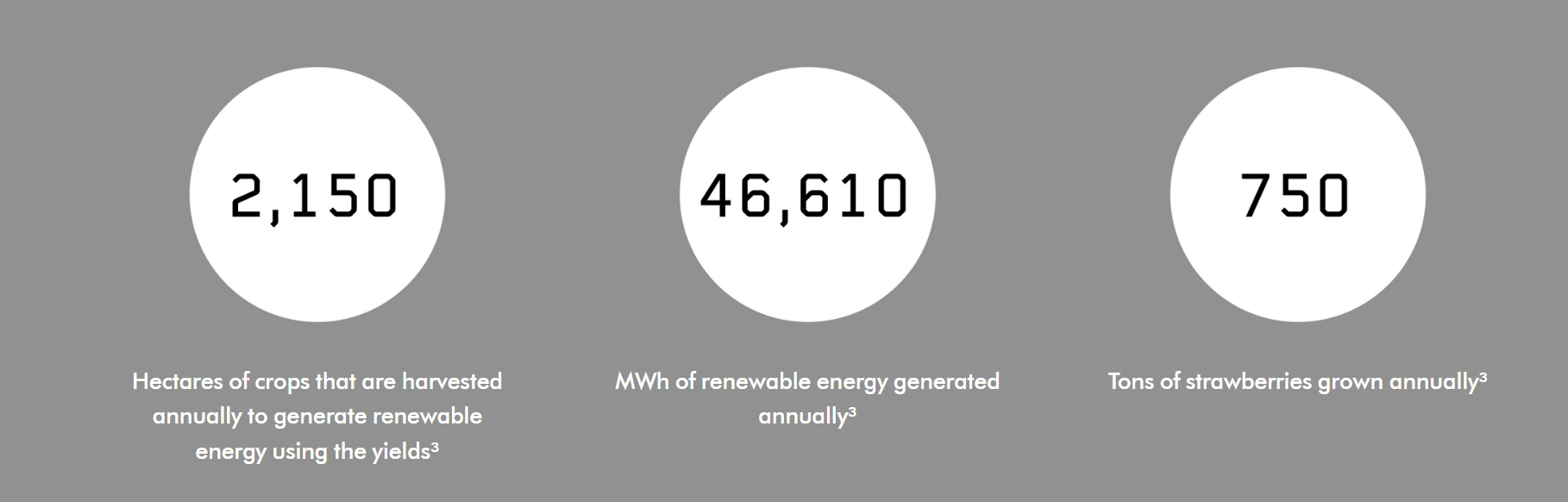

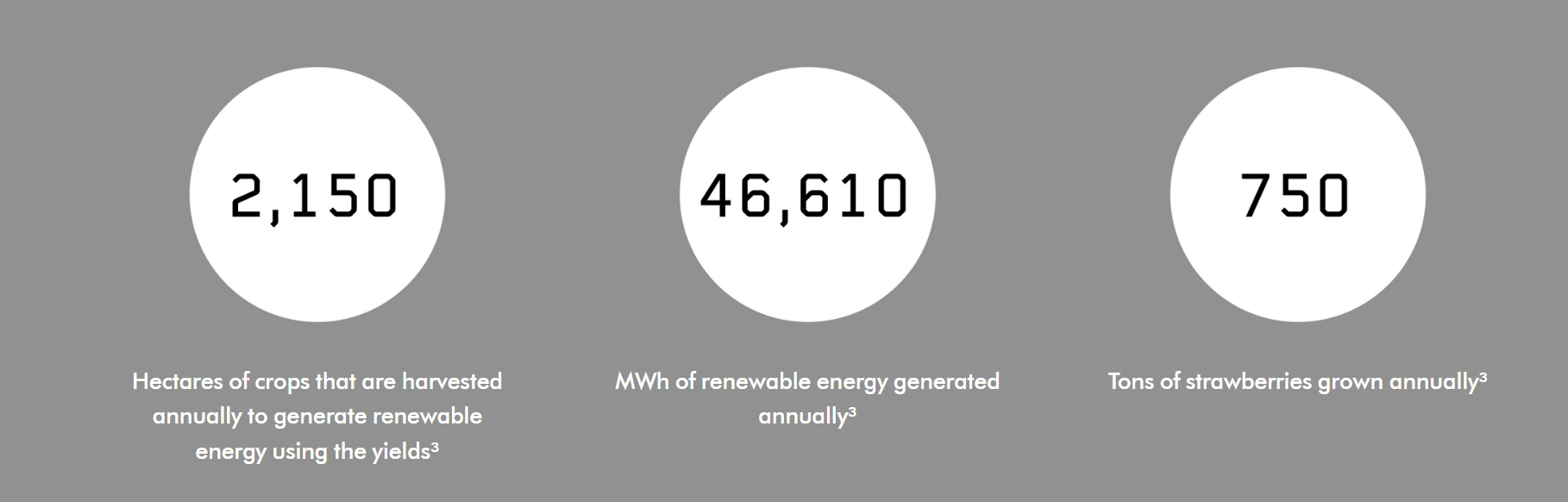

Agricultural circular system

We fuel our biogas plants with crops to generate renewable energy. The heat produced during the process is used in our greenhouse to promote fruit growth. Furthermore, we plan to capture the biogas in the future and convert it into biofuel, which can then be used to power vehicles.

Renewable energy

Dyson Farming generates enough renewable energy to theoretically power 10,000 homes. Generating renewable energy offers a great opportunity to make better use of the resources available to us.

Improving yield through technology

We use collected rainwater and excess heat from our biogas plants in our 6-hectare¹ greenhouse to grow strawberries even out of season. In this way, we help to reduce long import routes.

Re new

At Dyson, we constantly strive for innovation. This goes far beyond the devices we develop. Our approach is always focused on solving problems – including how and where we work.

Our headquarters, campus and our production facility

Our headquarters, campus and our production facility

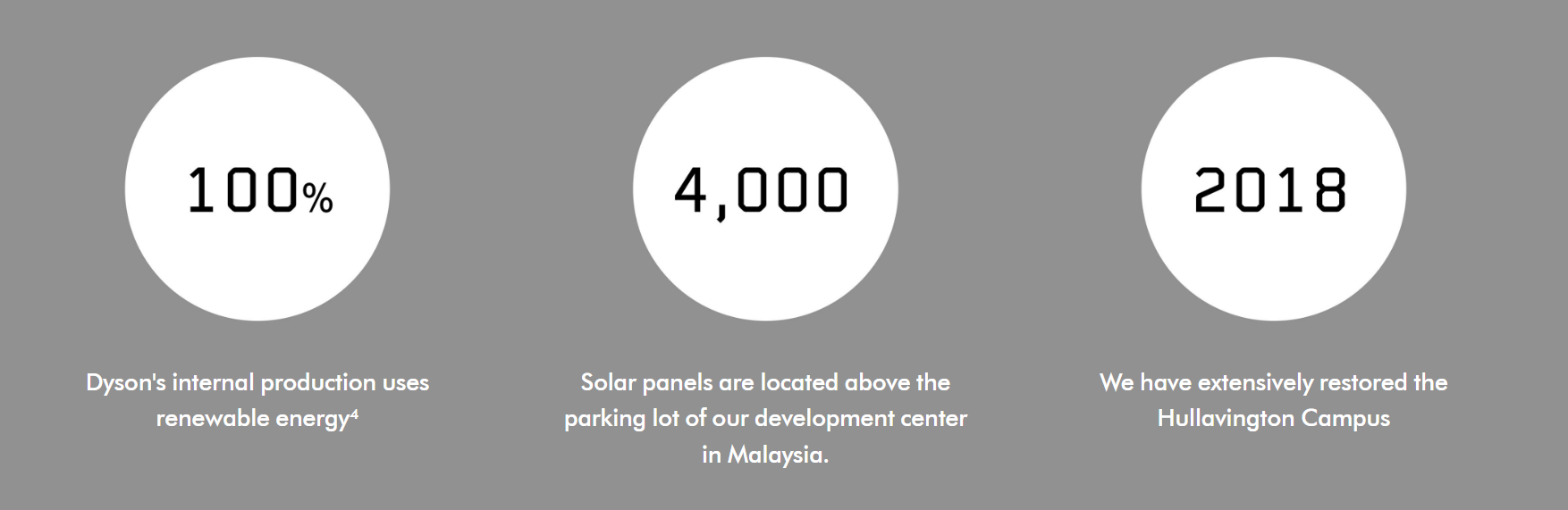

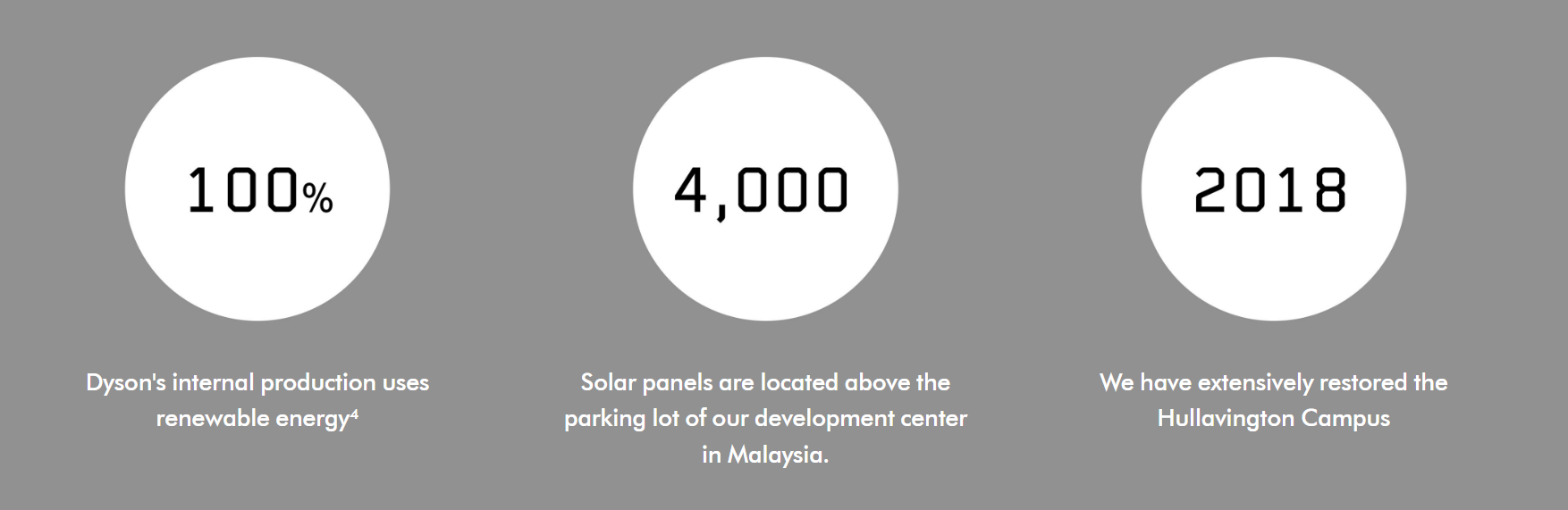

Our buildings use renewable energy

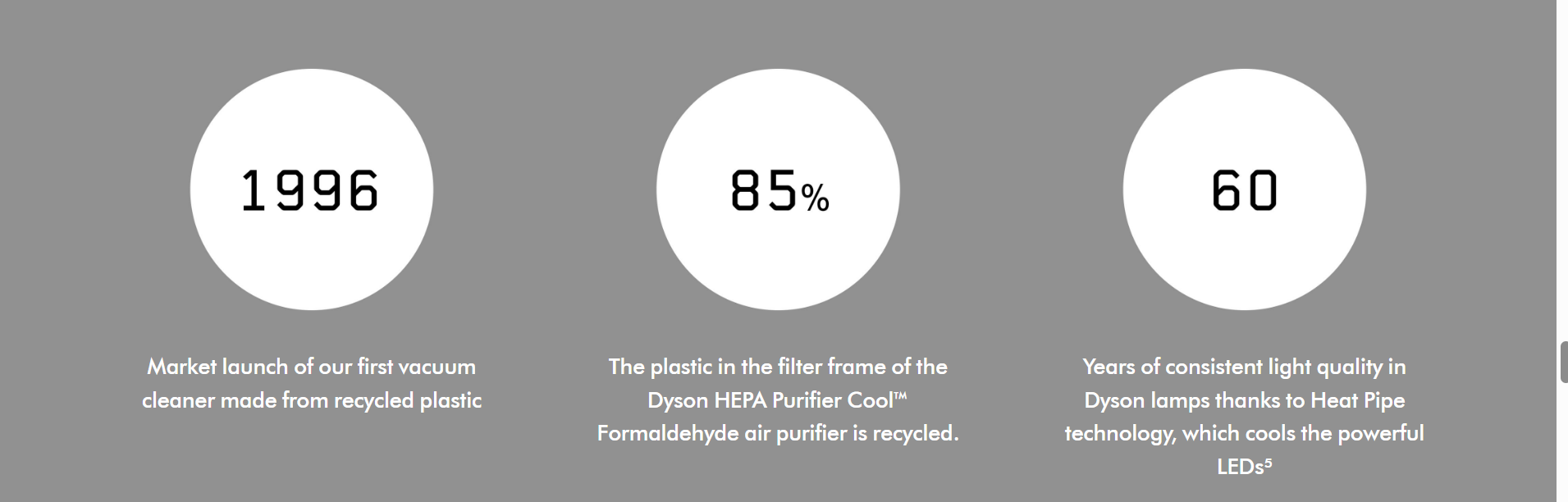

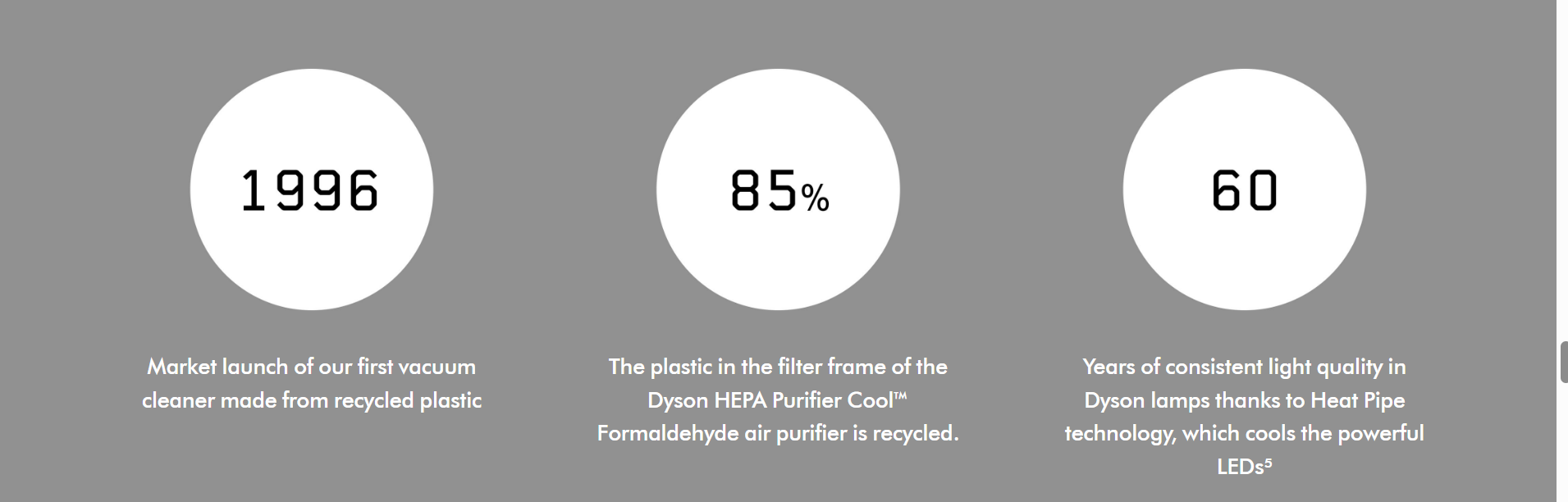

Since the end of 2022, 100% of Dyson's internal production has been powered by renewable energy. Furthermore, 65% of the electricity consumed at Dyson sites worldwide either comes directly from renewable sources or is certified through renewable energy guarantees.

St. James Power Plant

We restored the St. James Power Station in Singapore using environmentally friendly materials. In doing so, we optimized the building's energy efficiency and ensured that it uses electricity from renewable energy sources.

Malmesbury Campus

Our research, design, and development center is equipped with solar panels that supply electricity to part of the building. A geothermal heat pump located beneath the parking lot saves energy by ensuring a constant temperature regulation in the Lightning Café and cooling our IT server center.

Rethink

Our focus has always been on solving problems. We develop better technologies and make sure to use less material and energy in production.

Innovative core technologies to achieve more with less

Innovative core technologies to achieve more with less

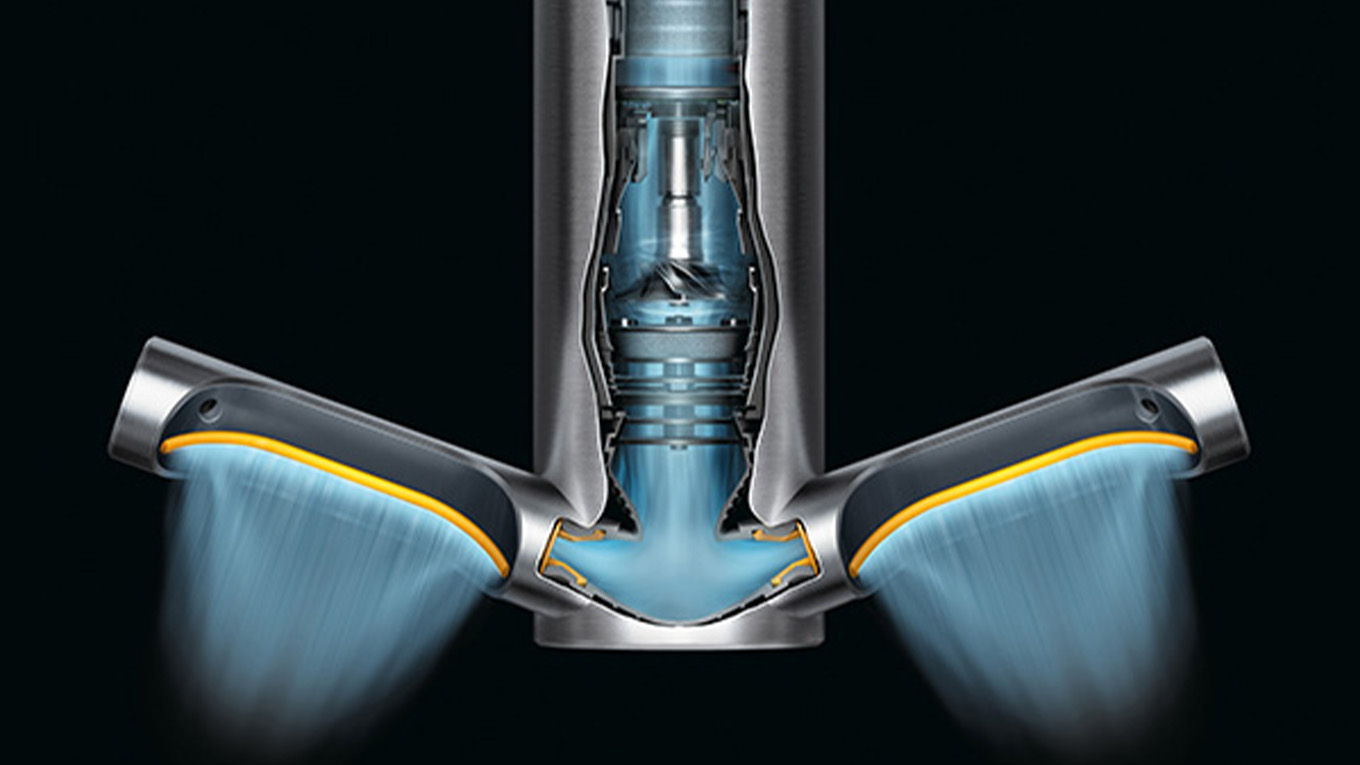

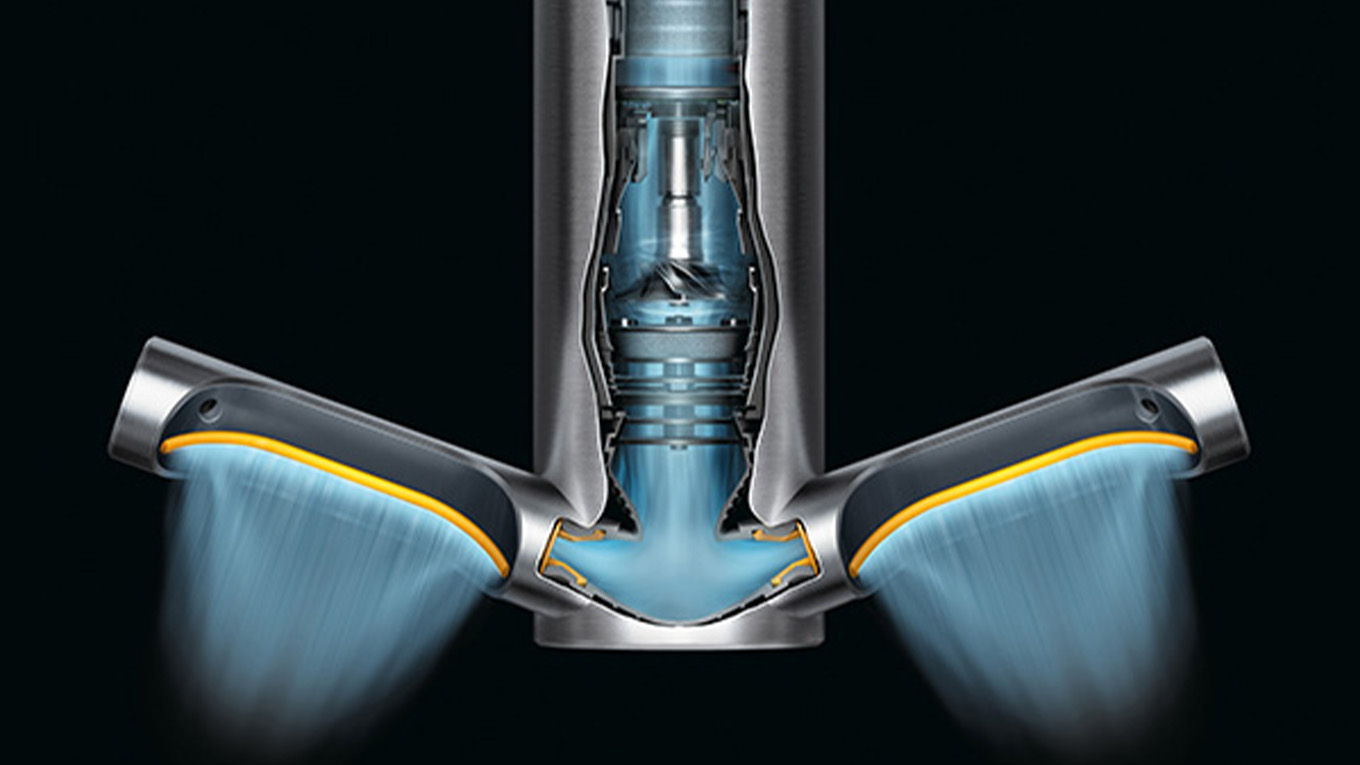

Revolutionary bagless vacuum cleaners

In 1993, we developed the Dyson DC01 – a vacuum cleaner that used centrifugal force to separate dust from the air. This made it more efficient and powerful than conventional vacuum cleaners. The dust bag became obsolete. Others followed our example, ensuring that dust bags are now increasingly a thing of the past.

New engine technology

Conventional brushed motors are heavy, bulky, and consume more power. Therefore, we set ourselves the goal of developing a motor that performs better. The result was the Dyson Digital Motor, which has enabled us to develop new technologies across various product categories.

Designed for low energy consumption

In Eco mode, the Dyson Airblade 9kJ hand dryer, for example, saves up to 99% on CO2 emissions compared to paper towels. And with an airflow speed of 542 km/h, it consumes only 13% of the energy of heated air hand dryers.

Refurbished Dyson technology

Our devices are designed for a long lifespan, so they need to be replaced or recycled less often. By refurbishing our products, we can further extend their lifespan and thus require fewer new parts and raw materials.

1 The figures are given in British currency.

2 In August 2023.

3 Farms in the United Kingdom; data from 2022.

4 Since the end of 2022, 100% of Dyson's internal production has been powered by renewable energy. Furthermore, 65% of the electricity consumed at Dyson sites worldwide either comes directly from renewable sources or is certified through renewable energy guarantees.

5 The LED lifespan calculation is based on the L70 measurement according to the EN 62717 standard, with an estimated usage of 8 hours per day. Actual results may vary.